In 1989, the brothers and entrepreneurs Jan G. Smith and Leif Smith founded ABIGO Medical AB, with a focus on delivering innovative methods of infection control and to reduce the use of antibiotics. ABIGO is a company with a substantial international presence and a continuing strong growth. Its products are sold in 70 countries, with a current turnover of about 30 million euros. The company’s workforce consists of more than 130 employees.

The founders and owners of ABIGO Medical, Jan G. Smith (left) and Leif Smith (right).

„Sorbact® is one of ABIGO’s key products and offers fantastic opportunities, particularly in view of the global challenges of infections and antimicrobial resistance,” Jan G. Smith, owner and CEO at ABIGO Medical explains. Sorbact® is a wound dressing that prevents infections and helps to reduce the need of antibiotics, hence lessening the risk of spreading multi-resistant bacteria. Excellent results in international studies combined with many years of clinical experience, has led to a sharp increase in the use of Sorbact®.

In order to meet the strong demand, ABIGO has invested 3 million euros in an expansion of the production facility, now 5,000 sqm and inaugurated in November 2016. The strong and continuous growth requires close partnership in all aspects of the product process. Harro Höfliger is a close companion to ABIGO for the production of the Sorbact® dressing. “Together we have grown over the past few years and we have established a lot of trust,” says Hartmut Thier, leader of the Harro Höfliger web converting team.

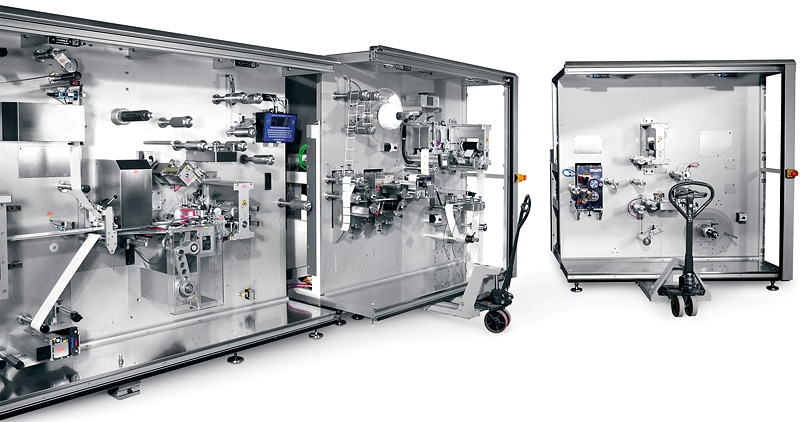

Rapid changeover to other product variants is possible due to the modular design of the PMK.

ABIGO’s Plant & Production Director Fredrik Stenbäcker affirms the good cooperation between the companies: “At ABIGO we promote a down-to-earth corporate culture without the hectic frenzy of continuously focusing on quarterly performance. We believe that people are buying from people. That’s why we highly appreciate that cooperation with the Harro Höfliger team always take place on a professional and pleasant basis. And we feel outstanding loyalty.” This is a close collaboration that pays off for both sides. The first web converting machine type PMK in 2010 was followed by a second line in 2012. The third machine for the Askersund site, near Gothenburg, has already been ordered.

“The PMK’s modular machine concept offers perfect prerequisites for a flexible and optimized sequence of core processes such as coating, sealing, cutting, punching and packaging,” Fredrik Stenbäcker explains. Format changeovers or machine options with different numbers of components can be easily implemented due to the PMK’s modular design.

According to Jan and Leif Smith, the fight against infections and antibiotic resistance is of utmost importance. It is an incredibly large area and there are a multitude of applications for the innovations owned by ABIGO. “We have barely scratched the surface,” Leif Smith says.

About ABIGO Medical

- Founded: In 1989 by brothers and entrepreneurs Jan G. and Leif Smith

- Products: Non-prescription, prescription drugs, food for medical purposes and medical products

- Headquarter: Gothenburg, Sweden

- Production: Askersund, Sweden

- Annual turnover: 30 million euros

- Global representation: 70 countries

- Number of employees: 130

Download this article as PDF file

Photos: Lab of Ralf Reski, CreativeCommons BY-SA 3.0, Helmar Lünig