This containment concept offers the highest process stability and a validated saf-ety level up to the OEL value of 0.1 μg/m 3 during production. In order to achieve this low OEL level, the development focused on consistently minimizing powder dust. In addition, particular attention was paid to interface optimization (e.g. empty capsule feed). A simple cleaning concept complements these measures.

The Containment concept of the Modu‑C MS provides reliable technology for operator and environment protection.

Since gravimetric checks are prone to errors, Harro Höfliger offers a containment solution with an integrated 100% capacitive mass control for the drum dosing station in its Modu- C MS (Mid Speed). During production, the measured capacitive value is compared online with the scale value in order to meet the customers’ ac-curacy requirements. For simple cleaning during product changes, Harro Höfliger prefers dry cleaning. The benefits: No bacterial growth caused by moisture, no disposal costs for contaminated water, and reduced incrustation, facilitating the removal of powder particles from the machine surface.

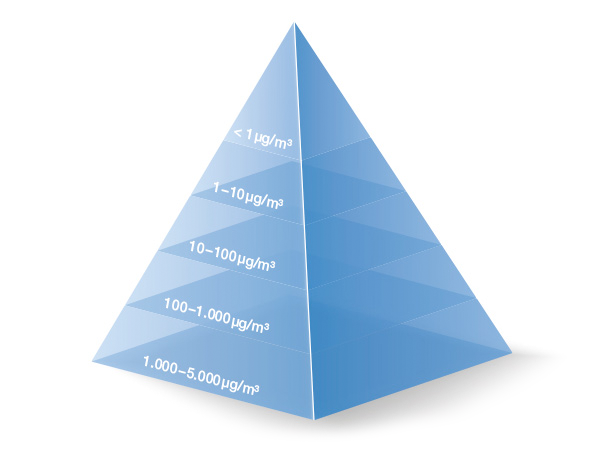

Occupational Exposure Bands (OEB) are defined on the basis of Occupational Exposure limits (OEl).

In addition, Harro Höfliger combines capsule filler, de-duster, metal detector and sampling in one compact system. Due to the standardized machine concepts of the capsule filling machines, all benefits mentioned can also be transferred to the Modu‑C LS (Low Speed) and the even more efficient Modu‑C HS (High Speed).

Download this article as PDF file

Photos: Helmar Lünig, Tom Philippi