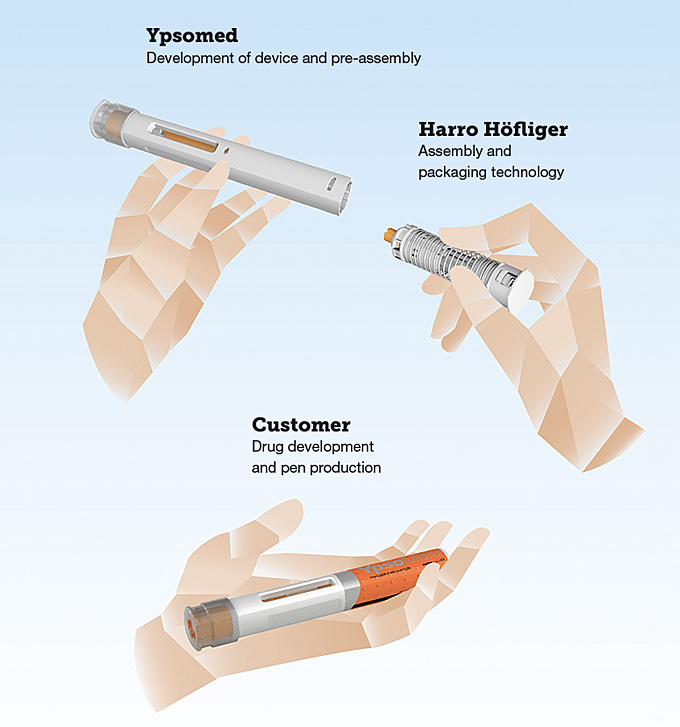

Pharmaceutical companies who want to launch an injection pen or an autoinjector are faced with several challenges. Once the active ingredient has been developed and is undergoing trials, the appropriate injection device has to be identified and market approval obtained. On the way to the finished product, pharmaceutical companies not only have to deal with approval authorities but also with various companies: the device manufacturer, the manufacturer of the filling machine as well as one or more manufacturers of assembly and packaging machines.

This involves a great deal of coordination. Harro Höfliger recognized this challenge at an early stage and has continuously expanded its service and consulting offerings.

Close partnership

A few years ago, the Swiss device manufacturer Ypsomed also responded to the need for comprehensive customer support by establishing a joint production network with Harro Höfliger. In the development of injection pens and auto-injectors, the device and machine manufacturer work hand in hand with pharmaceutical companies in order to address individual wishes and at the same time ensure rapid market launch.“

The Assembly Lab is a semi-automatic assembly machine for injection pens and auto-injectors. It is used for the final assembly of devices for small series and clinical studies.

For both the pharmaceutical customer and Ypsomed, reliable and timely cooperation with the machine supplier is essential in order to adhere to strict schedules,” says Orfeo Niedermann, Business Development Director at Ypsomed. While dosage, shape and color of the device can be adjusted at the customer’s option, the functional components are based on standardized platforms – both in the layout of the Ypsomed device and in the design of the assembly machines.

A strong partner who understands the device and the processes is extremely important. With their competence and experience in the field of semi-automatic pen assembly, we felt comfortable that the required quality would be met.“ Kristen D’Urso, Project Manager, Ambio, Inc.

Expertise

With their consulting services, Ypsomed and Harro Höfliger facilitate the entry into pen and autoinjector production and support companies in the expansion of their portfolios. Harro Höfliger’s Process Services, such as Engineering & Innovation Services, also play a helpful role. The experts in this special development department focus on careful and precise handling. They test material properties and optimize manufacturing processes with the aim of meeting the required quality standards even at high production speeds.

Orfeo Niedermann, Business Development Director, Ypsomed

What role does Ypsomed play in the production of injection pens and autoinjectors?

We advise customers on the optimum device for their purposes and recommend the appropriate machine manufacturers. We also support the final assembly at the pharmaceutical company or contract manufacturer by defining all parameters of the final assembly process and working closely with the customer and the machine manufacturer.

Why are Ypsomed platform products for self-injection so successful?

For years, Ypsomed has been investing heavily in patented innovations and pays great attention to the high degree of user-friendliness of their devices. The best technologies are implemented as flexible platform products and manufactured in highly automated processes, which enable high quality at attractive unit costs.

Allotted tasks

The complex pre-assembly of the injection devices takes place directly at Ypsomed. The device manufacturer can guarantee its consistently high quality through high-precision assembly and control processes. The pre-assembled devices are assembled with the syringes or cartridges and packaged at the pharmaceutical company or contract manufacturer. Filling of the active ingredient takes place at the pharmaceutical company or contract manufacturer on a special filling machine.

This is where a specialist for the filling of liquids such as Bausch+Ströbel comes into play. Due to the long-standing cooperation within the Excellence United network, the production lines of Bausch+Ströbel can be easily integrated into the lines of Harro Höfliger. The benefits of this close cooperation are also reflected in the project flow, thanks to reduced interfaces and collective expertise. Harro Höfliger offers tailor-made machine platforms from laboratory to full-scale production for both the final assembly and the subsequent packaging tasks of the devices.

Michael Kanzler, Leader Business Unit Assembly Automation, Harro Höfliger

Mr. Kanzler, what opportunities does the Assembly Lab offer for pharmaceutical companies?

On this semi-automatic, validatable laboratory machine, all critical processes can be tested and then transferred to the high-performance assembly machine.

Which areas of pen and autoinjector production can Harro Höfliger cover?

Harro Höfliger supplies assembly machines for the complex pre-assembly of devices. In cooperation with our Excellence United partner Bausch+Ströbel, we offer proven solutions for the filling of cartridges and syringes. In addition, Harro Höfliger also builds customized assembly and packaging machines for the subsequent steps from final device assembly to ready-to-ship packaging. Consulting, development, production and service for the entire project are thus provided from a single source.

Download this article as PDF file

Photos: Helmar Lünig, Janine Kyofsky, Ypsomed AG