More than three times around the world – this is the distance that the labels produced by Schreiner Group each year would cover if strung together. The company with headquarters in Oberschleissheim near Munich, Bavaria, was founded in 1951 and provides solutions for a wide range of applications. The portfolio comprises innovative functional labels including self-adhesive functional parts, RFID labels, printed electronics and security solutions for product and document protection, as well as customized services and value-added services.

The Schreiner MediPharm business unit specializes entirely in the requirements of the pharmaceutical and medical device industry. “There is a large demand for special labels in the healthcare sector, for example to optimally administer and track products,” explains Stefan Wiedemann, Senior Director Strategic Marketing and Business Development at Schreiner MediPharm. “With our high-quality labels, we are contributing to safe medical treatments.”

Each individual Needle-Trap label carries an accurately applied needle catcher.

Simple idea, easy application

Patient safety and the protection of medical personnel was also the driving factor behind one of Schreiner MediPharm’s greatest product successes, the Needle-Trap needle protection system. It addresses a pressing problem in healthcare: In European hospitals and medical practices alone, more than one million needlestick injuries occur every year. Schreiner MediPharm’s Needle-Trap secures the needle after injection, thus minimizing the risk of injury and helping to prevent infections.

“Our teams agreed that precision must come first, as the exact positioning of the needle catcher on the label is an important aspect.”Stefan Wiedemann, Senior Director Strategic Marketing and Business Development at Schreiner MediPharm

Stefan Wiedemann explains the idea: “A pre-filled syringe always requires a label containing all relevant information. This is where our Needle-Trap comes into play. We combine the label with an integrated needle catcher that serves to secure the needle after injection. Thus, to mark the pre-filled syringe, pharmaceutical manufacturers receive from us a label and a protective mechanism in one, a unique principle.”

Step by step toward higher safety

Its application is as simple as the idea: Prior to injection, users simply have to bend the needle catcher towards the side and remove the cap. The subsequent injection process is as usual and syringe handling remains unchanged. In order to activate the safety mechanism, the trap has to be pressed against a stable surface with one hand. An acoustic signal indicates when the needle is fixed in the trap and thus secured.

New challenges

Schreiner MediPharm has worked closely with Harro Höfliger since the beginning of product development. Hartmut Thier, Director Web Technologies at Harro Höfliger, describes the early stage of the collaboration. “Needle-Trap posed completely new challenges to web processing. While we had a lot of experience in label processing, the combination with the plastic part – the trap – was new. An initial test set-up quickly showed that our idea for the manufacturing process worked.”

Stefan Wiedemann summarizes the challenges: “Our teams agreed that precision must come first, as the exact positioning of the needle catcher on the label is an important aspect.”

“While we had a lot of experience in label processing, the combination with the plastic part – the trap – was new.” Hartmut Thier, Director Web Technologies at Harro Höfliger

A wide range of inspection systems

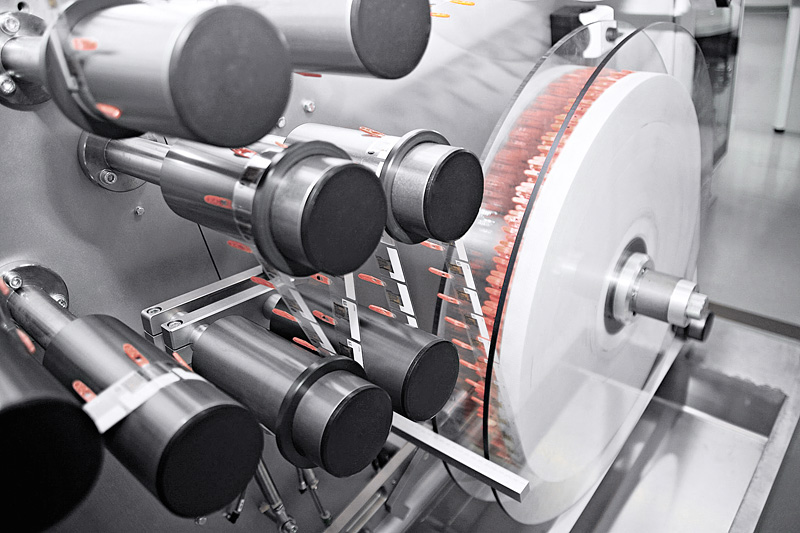

Based on these requirements, Harro Höfliger designed several production lines over the following years. These ensure that high-precision robots place a needle catcher on each label. At the same time, various inspection systems check whether all traps are perfectly positioned. “This inspection data goes into a digital batch report which enables end-to-end traceability. Thus, it is ensured that only flawless products leave the production lines in order to meet the high quality standards,” explains Hartmut Thier.

The finished Needle-Trap labels are exactly wound onto reels.

Quantity meets quality

To date, Schreiner MediPharm has produced more than 1.2 billion Needle-Traps on the joint machines. According to Stefan Wiedemann, this success is explained by the fact that the product meets the requirements of medical personnel and pharmaceutical industry alike. “Its compact design makes Needle-Trap an efficient and at the same time cost-effective solution. Demand remains high, since our needle protection system can be used for all common pre-filled syringes. And with machines from Harro Höfliger, we do not have to choose between high output and impeccable quality of each single product.”

Download this article as PDF file

Photos: Gernot Walter, Schreiner MediPharm, Janine Kyofsky