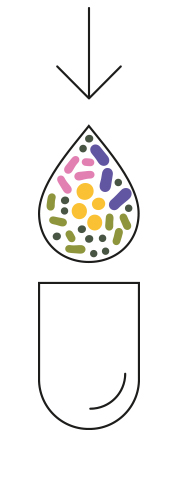

Every human body is home to many trillions of microorganisms, like fungi, viruses and bacteria. Together they form the microbiome whose composition is as individual as a fingerprint. But for all its uniqueness, every microbiome has one thing in common: It plays an important role in health. Our intestinal bacteria support digestion and protect against pathogens, for instance.

So the problem is all the more serious if this sensitive ecosystem gets out of balance. This could lead to a variety of health problems – like digestive disorders and inflammation.

“Live biotherapeutic products have the potential to treat a wide range of diseases.”Michael Philbrook,

Senior Director of Formulations

at Seres Therapeutics

Drugs with microorganisms

Live biotherapeutic products – LBPs – are based on specific strains of bacteria or other microorganisms. Their purpose is to restore balance. The US biotech company Seres Therapeutics specializes in such microbiome therapies. Its new drug – VOWST™ – is used to combat rCDI, a serious gastrointestinal infection. Michael Philbrook, Senior Director of Formulations at Seres Therapeutics, explains: “Recurrent CDI can occur after taking certain antibiotics, because while they fight harmful bacteria, beneficial bacteria are also significantly impacted. In a disrupted microbiome, the bacterium C. difficile can multiply and produce harmful toxins that cause severe inflammation of the colon and debilitating diarrhea.”

Although antibiotics are necessary to kill the toxin producing C. difficile bacteria, they do not address the disrupted microbiome, which may increase the risk of reinfection. That’s why Seres Therapeutics developed VOWST™ for such recurrent forms of infection: A capsule containing a mixture of different live bacterial strains which produce metabolites that end the cycle of recurrent C. difficile.

Capsule filling, a tricky business

The process for producing this promising drug is demanding. Michael Philbrook: “The bacteria are obtained from a healthy donor’s stool sample which is then purified, cleared of potential pathogens, and formulated to a target concentration. The process results in a stable bacterial spore suspension which is then filled into capsules.” These capsules are then over-encapsulated into a slightly larger size.

Harro Höfliger is the partner for all aspects of encapsulation. “This was based on our proven Modu‑C LS Containment machine,” explains Daniel Müller, Sales Director in the Capsule Technologies division. This includes a trolley system. Which means: The dosing systems are mounted on mobile carriages, making them interchangeable. This allows both processes to run on one machine.

Four steps to the perfect product

Fill liquid into capsule

Close inner capsule

Fill capsule into capsule

Close outer capsule

Two new developments

The first dosing station is for filling the liquid into the smaller capsule. Müller: “We’ve developed a dosing system that maximizes the filling efficiency so none of the valuable product is wasted.” Specialists then inspect each capsule outside the machine before over-encapsulation takes place again.

The Modu‑C LS Containment is set up to protect the operator while handling living organisms.

The second dosing trolley is now used for this purpose. “This is also a customer-specific development and an absolute novelty in the market,” says Daniel Müller. “So far, it was like this: When one capsule is filled into another, there was usually a two capsule size difference, e.g. a size 1 capsule in a size 00 capsule. This buffer did not exist here, however, because we are filling a 0 capsule into the next larger 00 capsule. In close coordination with Seres specialists, our engineers developed a perfect solution for this.”

High-tech cleaning

Handling living organisms requires special protection. Daniel Müller explains the background: “Even the slightest amount of bacteria left behind after one batch could contaminate the next one. Measures to prevent this include disinfecting with vaporized hydrogen peroxide (VHP). During this process, you can run the machine slowly with the doors open – thus ensuring that the gas reaches into every corner of the machine. A scanner is also integrated to check the area in front of the Modu‑C for safety reasons. If it detects a person, the machine stops immediately.”

“In close cooperation with Seres, we have developed two special dosing systems.”Daniel Müller,

Sales Director Capsule Technologies

at Harro Höfliger

“The equipment is tailor-made and precisely meets the exceptional requirements of this product,” Daniel Müller summarizes. “The close partnership with Seres contributed to the success of this design. We are always interested in exploring applications where new technologies must be found.”

Download this article as PDF file

Photo: Helmar Lünig