Harro Höfliger attaches great importance to supporting customers throughout the entire life cycle of products and machines. As with all other company divisions, the service offerings are regularly put to the test. What do customers need and which services can we provide to better support them? CEO Thomas Weller explains: “In order to be able to respond even more directly to our customers’ wishes, we have created the Process Services division headed by Stefan Mayer. Under this umbrella we bring together all services which we can provide to assist customers in the development of a product from concept to market readiness.” What was missing for a long time was a service component that specifically supports customers in the development or optimization of existing devices and medical products. Starting last summer, the so-called Device Services, which are also managed by Stefan Mayer, now perfectly complement our service offerings.

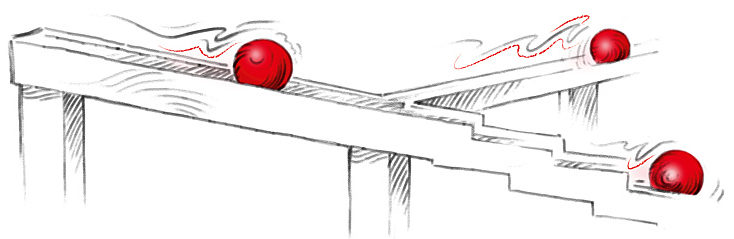

(Illustration: Bernd Schifferdecker)

Everything has to fit

With the creation of the new service division, Harro Höfliger also responded to the increasing number of customers who are seeking support for their own product development. “Of course, first and foremost we are machine engineers,” explains Stefan Mayer. “But careful consideration of what is filled and processed on our machines is essential for their design. An optimally designed device is just as important for the successful overall process as perfect product development processes, which we have been ensuring for many years with our Pharma Services.” Thomas Weller adds: “Our customers rightly rely on us to develop processes that can be implemented one-to-one from the laboratory machine to intermediate sizes to high-speed machines. It is only logical that we contribute to the commercially optimal production of a device with this new service component. This expertise allows us to offer a complete solution package.”

An optimally designed device is just as important for the successful overall process as perfect product development processes.“Stefan Mayer, Leader Process and Device Services

Customers benefit from the fact that the four departments within Process Services are closely interlinked. The Device Services experts work hand in hand with their counterparts at Pharma Services, who provide support in process selection, development and optimization at an early stage of product development. The specialists in the Engineering & Innovation Services division, in turn, assist with innovation projects, design test and trial setups, conduct feasibility studies and build prototypes. The focus is always on product safety and the development of proven, robust machines and processes which can be qualified or validated by our Validation Services employees.

An eye on details

Customers can benefit greatly from the support rendered by Device Services. For example, the FDA (US Food and Drug Administration) regulations regarding device optimization have become more strict. In the future it will no longer be so easy to change individual production steps after an approval, even if they do not fundamentally interfere with the function of the device. Every subsequent change inevitably means a great deal of effort, in the most serious case even a new approval, resulting in lost time and high costs. It therefore pays to design an inhaler or injector right from the start so that it is suitable for all production stages up to series production on a high-end machine without later adjustments.

“This complementary expertise of our Device Services specialists allows us to offer our customers a complete solution package.“ Thomas Weller, CEO

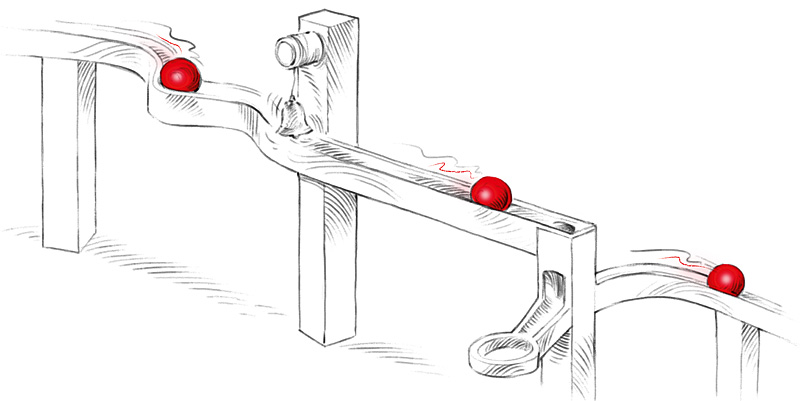

The often complex joining processes of devices, that often consist of small components, can be reliably tested in trial applications at Harro Höfliger. And in the case of pre-developed devices, our specialists have a keen eye for detail. For example, an infeed angle that perfects a good device. “In addition to our knowledge in mold making and material science, our many years of experience come into play,” explains Mayer. “We have worked with countless devices from customers and have also developed our own with the XTray®. This gives us a sense of what a product should look like and where there is still room for improvement.”

Our Device Services specialists also take care of the extensive, quite complex development of proper documentation, which is very demanding. We need to be familiar with International standards in order to ensure compliance. For example, specifications on how to structure device history documentation according to 21CFR820 and which risk analyses and tests are mandatory according to the ICH Q9 Guideline.

(Illustration: Bernd Schifferdecker)

Ideal conditions

Harro Höfliger invested heavily in the new Process Services division. This began with additional manpower and training, such as for the new documentation department. But it also entailed an investment in equipment and new cleanrooms. In addition to the four newly installed cleanrooms equipped with humidity and temperature control, six more will go into operation in the fourth quarter of 2018. In two of them even highly potent substances up to level OEB 5 (permissible exposure limit of less than 1 µg / m3 breathing air) can be tested. A special airlock technology makes sure that no substances spread to the outside.

New laboratory equipment such as a New Generation Impactor – a device that makes it possible to better map the aerodynamic behavior of inhaled drugs – will allow even more precise preliminary studies by both Pharma Services and Device Services. Stefan Mayer: “Our customers are demanding more and more trials with their own active ingredients and products on our machines. After all, such a system is a big investment and customers want to be sure that ultimately everything works just as it should. Our goal is to provide this assurance.”

Download this article as PDF file

Graphic: Bernd Schifferdecker, Photos: Janine Kyofsky