The demand for devices aiding allergy diagnosis is growing, reflecting the steadily rising number of allergy sufferers worldwide. Children are also showing symptoms of allergies at an increasingly earlier age. This often includes colds and itching, but also headaches or asthma. This development is particularly noticeable in industrial regions such as Europe, the United States or Japan,” explains Magnus Askvid, Manager Production Engineering at Thermo Fisher Scientific in Uppsala, Sweden. He considers these regions the key markets for the ImmunoCAPTM assays, the company’s proven diagnostic tool for decades.

„For us it was important to entrust a partner with the development of the machine, who can confidently respond to changing requirements.”Magnus Askvid, Manager Production Engineering at Thermo Fisher Scientific

An allergic reaction is always an overreaction of the immune system to a certain, often harmless substance that is recognized as foreign. It then forms antibodies, so-called immunoglobulins that can be detected with a CAP-test (carrier-polymer-system). With its quantitative detection of specific immunoglobuline E (IgE), ImmunoCAP™ Specific IgE makes it possible to determine sensitization at an early stage, often before clinical symptoms have developed in a patient. IgE detection is nothing more than counting antibodies for a specific allergen in the blood. “With ImmunoCAPTM it is possible to test sensitization to well over 500 different allergens,” says Magnus Askvid.

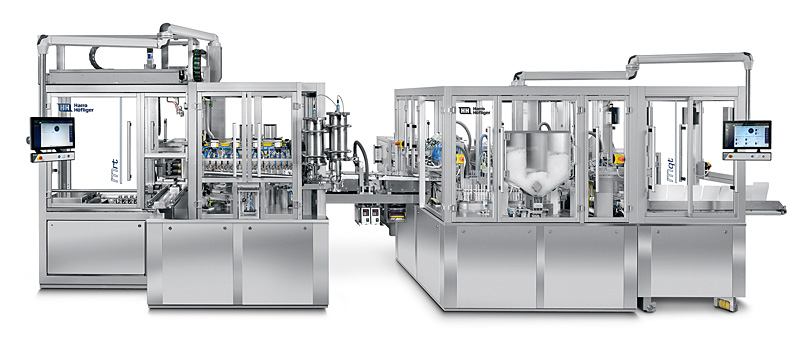

The assembly system of the ImmunoCAP™ test dispenser consists of intermittent machines.

The test principle

For the IgE test, the physician takes blood from the patient’s vein or a capillary vessel. The obtained serum or plasma is added to the ImmunoCAP™ Allergen in a laboratory system and the number of the respective antibodies is determined. The result can confirm or rule out allergen sensitization. An allergy diagnosis is then made by the physician, based on a detailed medical history and further clinical examinations. “The measurement of the IgE antibodies circulating in the blood, however, enables an objective assessment of sensitivity to an allergen and helps the physician to prepare an allergen avoidance strategy and an individual treatment plan,” explains Magnus Askvid.

Long-standing partner

Harro Höfliger has been supporting Thermo Fisher for more than three decades with the product assembly of the ImmunoCAPTM test dispenser. At the end of 2017, the fifth machine was delivered to Uppsala. In this system, the individual parts of the ImmunoCAPTM test dispenser are fed as bulk material to two coupled machines. Separated in units of 15, the first machine pushes the caps into an intermittently rotating turret. Its first station serves to insert the sponges which are punched in parallel from fleece soaked in liquid. A camera controls the presence and position of the punched parts. Subsequently, the pass-caps are moistened with buffer liquid. This is again followed by an optical dosage control. Any fail-parts will be rejected. The caps are then conveyed to the next intermittent machine, where the dispenser tubes begin their journey.

Design and structure of an ImmunoCAPTM test dispenser

The ImmunoCAPTM test dispenser consists of five components. A plastic tube, the eponymous dispenser, carries a certain number of so-called caps in it. Each of these caps contains a sponge soaked in liquid. At the front, the dispenser is closed with a removable plastic hat and at the back with a stopper. A weight between the stopper and the last cap ensures that the caps can easily slide forward and be removed automatically by the laboratory system.

Here, a camera checks the plastic tubes for damage before they are filled with caps. By recipe pre-selection, the fill quantity of the dispenser can be varied from ten to 16 caps. A slight vibration of the tube after insertion ensures that the caps slide into each other easily. A mechanical fill level control checks the tubes for correct filling. A weight is placed on the last cap and its presence is confirmed mechanically. The stopper closes the ImmunoCAP™ test dispenser at the back end. In the last assembly step, the hats, which are fed via a spiral conveyor, are fitted. Grippers place all good dispensers into folding boxes in layers of ten.

About Thermo Fisher Scientific

![]()

Thermo Fisher Scientific Inc. is the world leader in serving science, with revenues of more than 20 billion dollars and approximately 65,000 employees globally. The mission is to enable customers to make the world healthier, cleaner and safer. Through the premier brands – Thermo Scientific, Applied Biosystems, Invitrogen, Fisher Scientific and Unity Lab Services – the company offers an unmatched combination of innovative technologies, purchasing convenience and comprehensive services.

Download this article as PDF file

Photos: shutterstock.com/viewgene/cloik/Tim UR; istockphoto.com/Eraxion; stock.adobe.com/monebook, Helmar Lünig